Cold Room Insulation Panels-A Complete Guide on Insulating a Cold Storage Room Using Rigid Foam Insulation

Overview Cold storage rooms are mostly known as an essential for keeping perishable items fresh, regulating temperature, as well as avoiding spoiling. To guarantee that these areas stay consistently cool, save energy use, and maintain the quality of stored goods, proper insulation is crucial. We will go over all the ins and outs of insulating a cold storage room in this extensive guide, with an emphasis on using rigid foam insulation.

Recognizing the Value of Insulation It’s important to comprehend the need of insulation before getting into the mechanics of insulating a cold storage room. By acting as a barrier, insulation stops heat from being transferred from the inside to the outside environment. Effective insulation lowers energy costs, helps maintain low temperatures in a cold storage room, and guards against temperature changes that can jeopardize the integrity of goods being stored.

Cold Room Insulation Panels -Think About When Insulating a Cold Storage Room

Temperature Control:- cold room insulation panels

For refrigerated storage, cold storage rooms usually need to be between 0°C and 4°C (32°F and 39.2°F), or even lower for frozen commodities. These constantly low temperatures must be maintained by the insulation material.

Moisture Management:

In cold storage settings, moisture can be a major problem. In addition to acting as a vapour barrier, proper insulation should also stop condensation and moisture buildup, which can cause stored things to corrode, mould, or mildew.

Sturdiness and Lifespan:

Insulation used in cold storage rooms needs to be robust enough to endure the severe circumstances of a cold climate. To guarantee long-lasting function, it should be resistant to compression, moisture damage, and deterioration over time.

Energy Efficiency:

Over time, substantial cost savings can be achieved with an energy-efficient insulating solution. Seek for high-value (R-value) insulating materials to minimise heat transmission and lessen the strain on refrigeration systems.

Rigid Foam Insulation For Cold Room:

The Best Option for Cold Storage Rooms For cold storage applications, rigid foam insulation—also referred to as foam board insulation—is a preferred option because of its superior durability, moisture resistance, and thermal resistance. In our previous post, we may read, Firestone Rigid Insulation, still not then click and read-

Rigid foam insulation works effectively as cold storage room insulation for the following reasons:

High Thermal Resistance (R-value):

Compared to more conventional materials like fibreglass or cellulose, rigid foam insulation often offers a higher R-value per inch. The cold storage room’s great thermal resistance aids in preserving a constant temperature.

Resistance to Moisture:- rigid foam insulation for cold room

Because rigid foam insulation is naturally moisture-resistant, it is a great option for cold storage settings where condensation may be an issue. To insulate the cold room it serves as a trustworthy vapour barrier, keeping out moisture as well as shielding items being stored from harm.

Versatility: Rigid Foam Insulation For Cold Room

There are several varieties of rigid foam insulation, such as polyisocyanurate (polyiso), expanded polystyrene (EPS), and extruded polystyrene (XPS). Every kind has distinct benefits, so you can select the one that best suits your needs and price range.

Simple Installation:

Whether you’re building a brand-new cold storage room or remodelling an existing area, installing rigid foam insulation is comparatively simple. It offers seamless covering and can be trimmed to size, glued, or mechanically fastened to walls, floors, and ceilings.

Durability:- rigid foam insulation for cold room

Rigid foam insulation is renowned for its longevity and durability, in contrast to certain conventional insulation materials that may deteriorate with time. Even in challenging conditions, it keeps its insulating qualities, guaranteeing dependable performance for many years to come.

Steps for Using Rigid Foam Insulation to Insulate a Cold Storage Room Let’s now go over

How To Use Rigid Foam Insulation to Insulate a Cold Storage Room:

Evaluate the Space:- rigid foam insulation for cold room

Start by evaluating the cold storage room’s size and configuration. Determine which surfaces—such as walls, floors, and ceilings—need insulation.

Select the Appropriate Rigid Foam Insulation Type:

Decide on the right kind of rigid foam insulation by taking into account your budget, moisture resistance, and preferred R-value. To find the ideal solution for your particular application, get advice from insulation specialists if necessary.

Prepare the Surface:

Make sure the surfaces that need to be insulated are clear of any impurities or debris, dry, and clean. This will encourage the insulation panels to adhere properly.

Cut the Insulation Panels to Size:

Determine the measurements of the walls, floors, and ceilings. Then, cut the rigid foam insulation panels to the right size with a utility knife or saw. Be sure to allow for expansion by leaving a tiny gap around the edges.

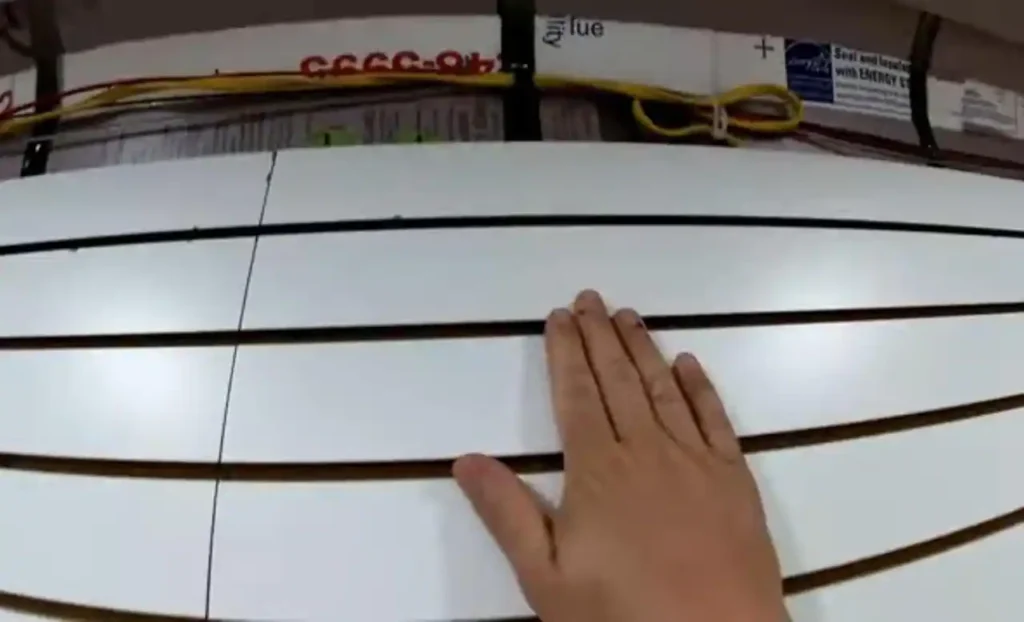

Assemble the panels of insulation:

The insulating panels should be fixed to the cold storage room’s walls, floors, and ceiling using adhesive or mechanical fasteners. Make sure there are no gaps or spaces between the panels and that they are firmly in place.

Seal the Edges and Joints:

To seal any seams or spaces between the insulation panels, use tape or foam sealant. This will improve the insulation’s efficiency and stop air leaks.

build a Vapour Barrier (if necessary):

To further stop moisture infiltration, you might need to build an additional vapour barrier over the insulation, depending on the particular specifications of your cold storage room. Experts in insulation can advise you on whether this step is required.

Finishing Touches:- Insulated wall panels for cold storage room

After installing the insulation, you can go on to other finishing touches like hanging plasterboard or other wall coverings. Throughout this process of insulate the cold room by using rigid insulation, make sure you abide by any applicable construction codes and regulations.

Routine Maintenance:

Check the insulation on a regular basis for signs of degradation or damage, and take quick action to fix any problems you find. Over time, proper maintenance will help guarantee that the insulation remains effective.

At the end we can say, by using rigid foam insulation to insulate a cold storage room is essential for sustaining ideal temperatures, protecting perishables, as well as cutting down on energy expenses. Through comprehension of the significance of insulation, selection of appropriate materials, and adherence to appropriate installation methods, you can establish a cold storage setting that fulfils your requirements for effectiveness, dependability, as well as durability. For better thermal performance and moisture resistance, rigid foam insulation is a flexible and cost-effective option for cold storage facility upgrades or new construction.

Insulated Wall Panels For Cold Storage

Insulated wall panels are revolutionary in the field of cold storage solutions, where temperature control is crucial. These cutting-edge wall panels are essential as well as useful in a variety of sectors, such as logistics, food storage, as well as pharmaceuticals, because these panels can able to provide a smooth combination of thermal efficiency, structural integrity, as well as adaptability.

Let’s set out to investigate the nuances of insulated wall panels for cold storage and reveal their revolutionary possibilities.

Gratitude Wall Panels with Insulation Sandwich panels, another name for insulated wall panels, are made of two layers of sturdy facing materials—usually metal sheets—sandwiched over a firm foam core. Outstanding thermal insulation qualities are provided by the core material, which is frequently made of expanded polystyrene (EPS), polyisocyanurate (PIR), or polyurethane (PU). In the meantime, the facing materials ensure endurance and durability by providing structural support and defence against environmental factors.

Examining the Advantages – Insulated wall panels for cold storage

Excellent Thermal Efficiency

Thermal insulation is a superior quality of insulated wall panels, which provide a barrier that reduces heat transfer between the interior and outside surroundings. This high degree of insulation panels in keeping cold storage facilities at consistent temperatures, protecting perishable commodities’ integrity and freshness.

Smooth Installation- Insulated wall panels for cold storage

The simplicity of installation is one of the insulated wall panels’ biggest benefits. Because these panels are prefabricated to exact specifications, on-site assembly may be completed quickly and smoothly. The panels’ lightweight composition and interlocking design further simplify installation, cutting down on labour expenses and shortening project schedules.

Improved Structural Soundness

Impressive structural integrity is a feature of insulated wall panels, despite their lightweight design. Panels with a strong foam core and sturdy facing materials are excellent for both interior and external applications since they can support large loads. Long-term endurance is also ensured by their resistance to corrosion and moisture, even in challenging settings.

Flexibility in Style

Unmatched design versatility is provided by insulated wall panels, which may be customised to fit specific needs. These panels can be made to match both functional requirements as well as aesthetic preferences thanks to a variety of core materials, thicknesses, colours, and finishes. With insulated wall panels, you can create temperature-controlled storage areas, walk-in freezers, or refrigerated warehouses with flexibility without sacrificing performance.

The Efficiency of Energy

Throughout a cold storage facility’s lifetime, insulated wall panels significantly reduce energy loss as well as help to minimise thermal bridging. Better insulation helps refrigeration systems operate more efficiently, which can help to lowers running costs because it has a smaller environmental impact. Insulated wall panels become a crucial element in attaining energy-efficient cold storage solutions as sustainability gains importance.

Uses and Applications for Cold Storage

There are several different cold storage situations where insulated wall panels are used, including:

Food Storage Facilities:

Insulated wall panels are essential for maintaining the safety and quality of perishable food items in cold rooms, distribution centres, and commercial refrigerators and freezers.

Pharmaceutical Storage:

To preserve effectiveness, temperature-sensitive drugs and vaccines need to be precisely regulated. The essential thermal insulation for the protection of pharmaceuticals during storage and transit is supplied by insulated wall panels.

Logistics and Warehousing:

To ensure the best possible conditions for products in transit, insulated wall panels are a crucial component of the building of refrigerated warehouses, cold chain logistics facilities, and temperature-controlled storage areas.

In summary, Increasing Cold Storage Effectiveness Insulated wall panels are a cornerstone of efficiency as well as dependability in the ever-changing field of cold storage solutions. They are very important in a variety of applications due to their exceptional thermal insulation, seamless installation, along structural stability.

How to Install Cold Storage Insulated Wall Panels

Cold storage facilities are necessary for increasing the product’s shelf life, A crucial element of these establishments are insulated wall panels, which offer heat resistance as well as establish a regulated atmosphere suitable for storage. So, here We will take you step-by-step through the installation of insulated wall panels for cold storage in this comprehensive tutorial.

1. Getting Ready for Installation

Gathering the required supplies and equipment and properly preparing the location are essential steps before beginning the installation process. What you’ll need is as follows:

Materials: Prefabricated, insulated wall panels

Fasteners (bolts or screws)

Adhesive or sealant

Tape for insulation

Vapour barrier, if necessary

Trims around the corners

Brightening (for gaps)

Tools:

screwdriver, drill, and driver

Level Tape Measure A utility knife

Caulking gun Safety gear, such as goggles and gloves

Measurement and Planning

Measurement and Planning of the Site Measure the cold storage area’s dimensions and decide how the insulated wall panels should be arranged first. Take into account elements like the locations of windows and doors, corners, and any other impediments. Arrange the panel arrangement to reduce cutting and guarantee a tight fit.

Wall Assembly

Make sure there are no obstructions or debris on the walls, and that they are dry and clean. Make sure the surface is flat and smooth, and repair any damage that already exists. Install a vapour barrier if needed to stop moisture from seeping in.

Panel Installation

a. Starting Point:

Ideally, start at the wall’s edge or corner that is furthest away from the entry. As you install the first insulated wall panel, make sure it is level and plumb. To confirm alignment, use a level.

b. Fastening:

Using the proper fasteners (bolts or screws), secure the panel in place. To ensure a secure attachment to the wall substrate, place fasteners at regular intervals along the panel’s perimeter.

c. Panel Alignment:

Make sure all panels have tight seams and a consistent appearance by aligning them with the first panel. Throughout the installation procedure, use a level to ensure that everything is aligned vertically and horizontally.

d. Cutting and Trimming:

Use a utility knife or saw to cut panels to size as needed. To keep the insulation intact, take precise measurements and cut with accuracy.

To hide exposed edges and provide a polished look, use corner trims.

e. Tape for sealing and insulation:

For an airtight seal, seal panel seams and joints with sealant or glue. This lessens the chance of air loss and thermal bridging. To improve the wall system’s insulating qualities, use insulation tape to close gaps and seams.

Bottom Line Of,cold room insulation panels /How to insulate a cold storage room/ rigid foam insulation for cold room

Through comprehension of the significance of insulation, selection of appropriate materials, and adherence to appropriate installation methods, you can establish a cold storage setting that fulfils your requirements for effectiveness, dependability, as well as durability. For better thermal performance and moisture resistance, rigid foam insulation is a flexible and cost-effective option for cold storage facility upgrades or new construction.

Here We shared and take overlook on, step-by-step through the installation of insulated wall panels for cold storage in this comprehensive tutorial.

Do let us know how you feel about this information by commenting.

Like our Facebook page and follow for other updates like this.