What is better blown in insulation or rolls; Full Examination: Roll Insulation vs. Blown-In Insulation

Selecting the appropriate as well as correct insulation is a crucial and essential choice for both commercial and residential homeowners. Two well-liked solutions stick out among the multitude of possibilities available: roll insulation and blown-in insulation. Here We will be going to examine and provide correct information on the nuances of each kind in detail, weighing the advantages and disadvantages, and helping you make an informed choice based on your unique requirements.

The hidden hero of homes is insulation, which quietly maintains our comfort levels by minimizing energy loss and controlling internal temperatures. Two alternatives that frequently stick out among the many that are available for insulation are blown-in insulation and roll insulation. Here we shall examine the specifics things about any of these insulation options in-depth, in this comprehensive guide, contrasting their R-values, methods of installation, and general efficiency.

Knowing the Basics: Roll vs. Blown-In Insulation

Let’s lay the groundwork for various insulation kinds before getting into the specifics. this insulation form is available in sustainable material, you may read the post, sustainable wall insulation, if not then click here-

Blown-In Insulation– what is better blown in insulation or rolls

Blown-in insulation, sometimes referred to as loose-fill insulation, is a type of insulation that is blown or poured into a space using loose fibers or particles. Mineral wool, cellulose, and fiberglass are often utilized materials. By creating a smooth and light coating that fits the contours of the area, the procedure effectively covers it. You may read the post, Benefits of Blown In Insulation. Now in next passage we share information about what is better blown in insulation or rolls and r value of blown in insulation as well as r value of roll insulation

Roll Insulation: – blown in vs roll

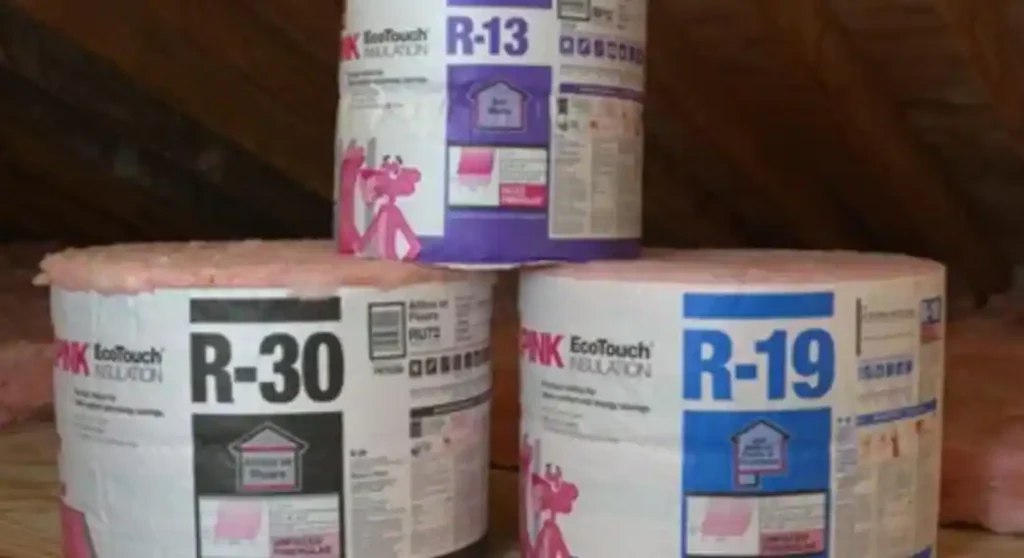

Also known as blanket insulation, roll insulation is made of pre-cut material, usually mineral wool or fiberglass, and is supplied in big rolls. It is intended to be rolled out and cut to size to slide in between wall, ceiling, and floor framing. It’s an economical and adaptable solution that’s often chosen or selected for its simplicity of installation.

Blown Insulation vs Roll

A Comparative Study of Roll and Blown-In Insulation

Let’s now carry out a thorough comparison analysis to help you decide which option best suits your needs.

Blown in Insulation

1. The complexity of installation for blown-in insulation

Advantages: Professional installation is necessary to provide maximum coverage and efficacy.

Cons: Hiring a professional installer could increase initial expenses.

Insulation in rolls:

Advantages: Easy to assemble on your own, making it a budget-friendly choice for people who are handy with installation.

Cons: Blown-in insulation may fill uneven spaces more precisely than this type of insulation.

2. Consistency of Coverage: Blown-In Insulation

Advantages: Offers reliable coverage that efficiently fills in holes and spaces.

Cons: To ensure correct application, professional experience is required.

Insulation in rolls:

Advantages: Generally reliable, however, it could be not easy to get a perfect fit in asymmetrical areas.

Cons: If not put precisely, it could leave gaps.

3. Effectiveness of Energy Use:

Blown in Insulation

Advantages: It uses less energy since it can reduce air leaks and offer even coverage.

Cons: For best performance, professional installation is required.

Insulation in rolls:

Advantages: Offers good insulation, but because of possible gaps, it might be a little less energy efficient in some situations.

Cons: Uneven coverage may come from do-it-yourself installation.

4. Cost-effectiveness:

In-situ insulation

Advantages: Usually more costly upfront, particularly for expert installation.

Cons: The initial costs might be offset by long-term energy savings.

Insulation in rolls:

Advantages: Generally more affordable, which makes it a desirable choice for households on a tight budget.

Cons: Because of possible decreased efficiency, there may be greater long-term energy expenses.

5. Recycling Existing Structures:

Inlaid Insulation

Advantages: Because it can fill existing holes without requiring significant structural alterations, it is perfect for retrofits.

Cons: For retrofit work, professional experience is advised.

Roll Insulation

Advantages: It can be retrofitted, but it might need additional work to make sure it fits properly in existing structures.

Cons: For certain homeowners, DIY retrofitting may be difficult.

Making a Smart Decision between blown in and roll insulation

When it comes to the debate between roll and blown-in insulation, there isn’t a universal solution. The best option will rely on a number of things, such as your comfort level with do-it-yourself installations, the nature of your job, and your budget.

Select Blown-In Foam Insulation If

Energy efficiency and smooth coverage are your top priorities.

Installing professionally is within your means.

An existing structure with uneven spaces is being retrofitted.

Select roll insulation in the following situations:

You have a limited budget and feel at ease with DIY installation.

Your project involves simple, easily navigable areas.

For locations that are prone to moisture, integrated vapor barriers are essential.

Think about speaking with experts in insulation to receive tailored advice based on your particular needs. Creating a cosy, energy-efficient living area that fits your unique needs and preferences is the ultimate goal, regardless of whether you choose the accuracy of blown-in insulation or the ease of roll insulation.

R-Value Comparison: An Essential Metric

An important consideration in the evaluation of insulation is the R-value. It measures a material’s ability to endure heat flow by measuring its thermal resistance. The performance of

the insulation is better the higher the R-value. Let’s examine the R-values of roll and blown-in insulation.

R value of blown in insulation

Fiberglass Blown In Insulation– r value of blown in insulation

Insulation that is blown in Value at R Fibreglass Inlaid Insulation usually features an R-value between 2.2 and 2.7 per inch.

Cellulose Blown Insulation R-value of cellulose blown-in insulation ranges from 3.2 to 3.8 per inch.

R Value of Roll Insulation

Fibreglass, Roll Insulation– R value of Roll Insulation

R-Value Typically, roll insulation offers an R-value of 2.9 to 3.8 per inch.

Mineral Wool Roll Insulation

The R-value of mineral wool roll insulation ranges from 3.1 to 4.2 per inch

Blown Insulation vs Roll and Benefits of both insulation material

The Roll Insulation Benefits:

Easy to Do Yourself Installation:

Because roll insulation is so simple to install, DIY enthusiasts usually favor it. Without the use of specialized tools, homeowners may unroll the material, reduce it to fit, and attach it in place.

Affordability:

The affordability of roll insulation is one of its main benefits. The material itself is frequently more affordable than any other material, and the ease of installation can help to further save project expenses.

Application Versatility: blown in vs roll

Roll insulation is adaptable and works well in a variety of settings, such as floors, walls, and ceilings. Because of its adaptability, it can be quickly adjusted to various framing configurations.

Integration of the Vapour Barrier:

A lot of roll insulation products have built-in vapor barriers. Because of this characteristic, roll insulation is a dependable option for areas that are prone to humidity and helps prevent concerns linked to moisture.

Benefits of Blown in Insulation:

Seamless Coverage

blown-in insulation is quite good at forming a smooth, even layer. There is nowhere for air to leak because the substance seals up holes, crevices, and difficult-to-reach places. As a result, there is a constant thermal barrier, improving energy efficiency.

Versatility and Ease of Installation:

Insulation that is blown in is especially useful in attics and other irregularly shaped spaces. By utilising specialised equipment to blow in the material, it can easily conform to the shape of the area. It is therefore the best option for retrofitting already-existing structures.

Energy Efficiency:

Blown-in insulation reduces air penetration and exfiltration since it can fit into every nook and hole. This tight seal lessens the strain on heating and cooling systems and makes a major contribution to energy efficiency.

What is better Blown in insulation or Roll insulation-

Both roll insulation and blown-in insulation have advantages, and the best option will rely on a number of variables, including your comfort level with DIY projects, your budget, and the particular space you’re insulating. While roll insulation is less expensive and better suited for simple installations, blown-in insulation provides smooth covering and is best for uneven spaces. Here, in the following passage, we will share detail post about, insulation installation-

Roll insulation and blown-in insulation are two common insulation techniques. We will take you through each method’s step-by-step procedure in this comprehensive guide, enabling you to make an informed choice based on your unique requirements.

The Installation Guide For Blown-In Insulation

Step 1: Examine Your Space– Blown insulation vs roll

The first step of the installation guide for blown-in insulation is preparation and assessment.

Examine Your Space: Examine the area you intend to insulate before beginning the installation. Determine which blanks, gaps, or anomalies require remedy.

Safety first: Make sure you are wearing the proper protective clothing, such as gloves, a mask, and goggles. Materials for blown-in insulation may irritate the skin and respiratory system.

Step 2: Setting the Equipment- what is better blown in insulation or rolls

Select the Appropriate Equipment: Make sure you select the right blowing machine for the material, whether you are working with cellulose or loose-fill fibreglass. Home improvement stores frequently rent out these equipment.

Get the Material Ready: Make sure the insulation material is well-conditioned and broken up for even distribution before loading it into the machine.

Step 3: The Installation Procedure

Commence at the furthest point: Working your way towards the exit, start the installation from the furthest place in the room. This keeps you out of the insulated region and prevents you from getting stuck.

Even Distribution: To disperse the insulation material equally, use the blowing machine. Give particular attention to any locations that could be vulnerable to air leaks, such as corners and edges.

Check for Gaps: Make sure there are no gaps or uneven covering by stopping from time to time. To guarantee uniform insulation, change the machine’s settings or manually fill in any gaps.

Repetition is required. Until the room is sufficiently insulated, keep going through this process. Make sure to cover crawl areas and attics equally throughout.

Step 4: Inspections After Installation

Check for Thickness: Check to see if the insulation has reached the appropriate thickness after finishing. Both the overall R-value and energy efficiency may be impacted by this.

Cleanup: Remove any extra insulation from the area. Over time, blown-in insulation may settle, so some extra material is expected.

Examine for Air Leaks: Look for any indications of insulation gaps or air leaks. Close up any gaps to guarantee optimal performance.

Installation Guide for Roll Insulation: Step 1: Planning and Measurement

Step 1: Calculate the Area- blown insulation vs roll

Measure the area that you want to insulate first. This comprises the height, breadth, and length of any floors, walls, or ceilings.

Determine Insulation Needs

Determine how much roll insulation is needed based on the measurements. Think about the R-value required for your area and climate.

Step 2: Take Safety Measures

Safety Equipment: Wear the proper safety equipment, such as gloves, a mask, and goggles, for this insulation project as well as any others.

Step 3: The Installation Procedure

Open the Document: The insulation material should first be unrolled along the length of the room. To guarantee a snug fit, cut the material to suit, leaving a small extra.

Staple or Fasten in Place: Use staples or other fasteners to firmly anchor the insulation in place. Take care of the edges and corners to avoid any gaps or drooping.

Multiple Layers: You can add more layers of insulation if a greater R-value is required. To prevent compression, make sure the layers are positioned perpendicular to one another.

Step 4: Inspections After Installation

Verify the Compression: Make sure the insulation hasn’t been compacted because doing so can lessen its efficiency. Expand any confined spaces.

Look for Gaps: Look for any places where the insulation may be uneven or gaps. Take care of these things to keep coverage consistent.

Seal Edges and Joints: To stop air leaks, seal any edges or joints. This is essential to preserving the insulation’s performance.

Final Thought, What Is Better Blown In Insulation or Rolls \ R Value of Blown In Insulation

There is no universal solution to the roll vs. blown-in insulation argument. The decision is mostly based as well as depends on the project type which you are going to do, according to your budget, as well as your unique needs and requirements. For those who prioritize and want to increase energy efficiency and uniform coverage, blown-in insulation may be the better choice. On the other hand, roll insulation can be the best option if you’re searching for an inexpensive fix that can be installed by yourself.

Think about speaking and consulting with insulation experts to determine and select material according to your unique needs and receive tailored advice. Whether you choose roll insulation for its ease of use or blown-in insulation for its accuracy, the result is a long-lasting, cozy, and energy-efficient home. So, this is full information about what is better blown in insulation or rolls and r value of blown in insulation as well as r value of roll insulation

Do let us know how you feel about this information by commenting.

Like our Facebook page and follow for other updates like this.